Our Quality Services

Lashing & Unlashing of Containers, General Cargoes, Stuffing & Unstuffing, Forklift Services, Packing & Unpacking, Tally & Cleaning .

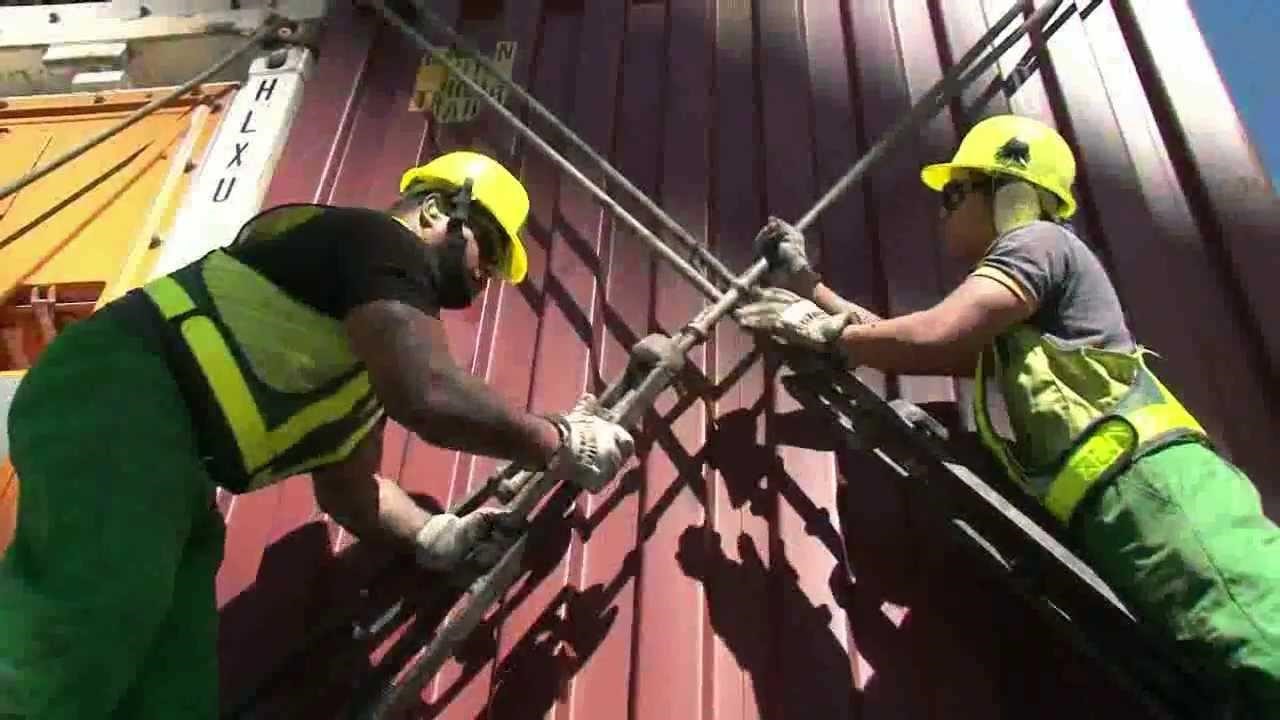

LASHING AND UNLASHING CONTAINERS

When a container is loaded over ships, it is secured to the ship’s structure and to the container placed below it by using lashing rods, turnbuckles, twist-locks etc. This then prevents the containers from moving from its place or falling off into the sea during rough weather or heavy winds. Normally, Stevedores are responsible for lashing and de-lashing jobs in port. However, due to less port stay and constraints of time, deck crews are also responsible for this operation. Before the arrival at the port, the ship's crew normally de-lashes the containers so that time can be saved in the port and the containers can be discharged immediately after berthing. The container Lashing is regularly checked by the ship’s crew to avoid any types of accidents due to improper lashing.

LASHING AND UNLASHING OF UNCONTAINERIZED CARGO

Cargos that exceed the

container payload or have dimensions affecting the use of the lifting points

are classified as Un-containerized Cargo (UC). The UC then will be placed on

flat racks or platforms; lashing and unlashing will be done onboard.

OUT OF GAUGE CARGO (OOG) / SPECIAL CONTAINER CARGO

Out-of-gauge cargo is freights which are too large to fit in any standard 20 ft, 40 ft or 40 ft high cube containers. Instead, any of these cargoes can be transported safely on a platform, flat rack or in an open top container.Any cargo in a dimension exceeding a standard container internal dimension is considered as an OOG. The maximum weight of a cargo should not exceed the safe working load of respective ports, which would be otherwise considered as an un-containerized cargo. Oversized and special cargoes, with their unique requirements, can be challenging. With years of experience shipping all types of cargoes, Defrans offer the expertise and knowledge to help in moving all types of cargoes safely and efficiently.

STUFFING AND UNSTUFFING

Stuffing is a process in which any cargo is loaded into an empty container which is then sealed (often in the presence of customs) and transported to the carrier for loading onboard a ship. Unstuffing is a term known and used widely within the logistic community for the unloading of cartons containing goods from a packed container.

PACKING & UNPACKING

For this service, the procedures begin when the workers are instructed to slit the import container seal by a Tally clerk. Then, they will either pack or unpack the cargo from the container. Once it’s done, cleaning, weighing and labelling on the packaging materials will be completed before loading the items into the containers. They will also perform final checks for defective items to ensure all are in working conditions before making it to the loading area or inventory and keep detailed records of materials and shipments. Our workers will examine and inspect the containers, materials, and products to ensure that packing specifications are met. Packagers are hand laborers who work in warehouses which put together packages. They might assemble packaging like boxes or crates, label and record what is packed, inspect packaging for tears, cracks and dents, and make sure the materials inside are packed in a way to minimize breakage during transit.

TALLY WORKS

Tally work is to examine and count cargo at, loading docks, warehouses and wharves. A tally clerk counts goods and matches them with shipping invoices and packing orders to ensure the accuracy of incoming and outgoing shipments. They record weights, measurements and dimensions of cargo. They will calculate storages, damages, shipping and receiving fees. The tally clerk will check, verify and tally the correctness of merchandise as against the invoice documents. They then will inspect and count items received and check them against invoices or other documents, recording shortages and rejecting damaged goods.

CLEANING SERVICES

When

cargoes that are on hold and presented for loading cargoes in bulk, they are

not sufficiently clean. This may cause delays, off-hire and charter party

disputes can arise. Insufficient cleaning can also cause cargo contamination

and infestation, leading to cargo damage claims from cargo receivers. Due to

the importance of the preparation and cleaning of cargo holds prior to loading,

personnel on vessels are also involved in preparing cargo holds, and those

ashore involved in fixing and operating vessels, should be familiar with the various

issues surrounding the cleaning of holds in order to prevent the possibility of

delays, disputes and claims.

Our Achievements

Contractor of choice in the Port and Shipping Industry.